Shop

Explore our unique collection of recycled goods designed for both homes and businesses. As a family-owned company, we are guided by four core pillars: Sustainability, Craftsmanship, Community, and Innovation.

Each product is a testament to our dedication—crafted with care and expertise to transform discarded plastics and waste into something new and meaningful.

Explore our unique collection of recycled goods designed for both homes and businesses. As a family-owned company, we are guided by four core pillars: Sustainability, Craftsmanship, Community, and Innovation.

Each product is a testament to our dedication—crafted with care and expertise to transform discarded plastics and waste into something new and meaningful.

Services

Supplier of Recycled Resin

We see plastic waste as a high end resource.We can supply an all Australian made recycled plastic with provenance.

Contact Us

Corporate Circularity Projects

We help Brands, Manufacturers & Recyclers turn their waste plastic into high-end next generation products.

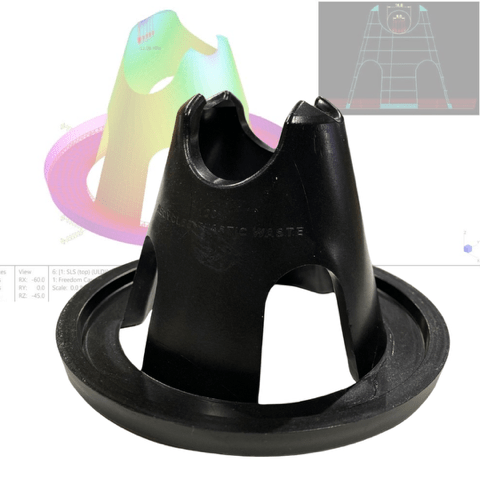

Product Design

We are always happy to work with you to explore potential new products! We can help with product designs.

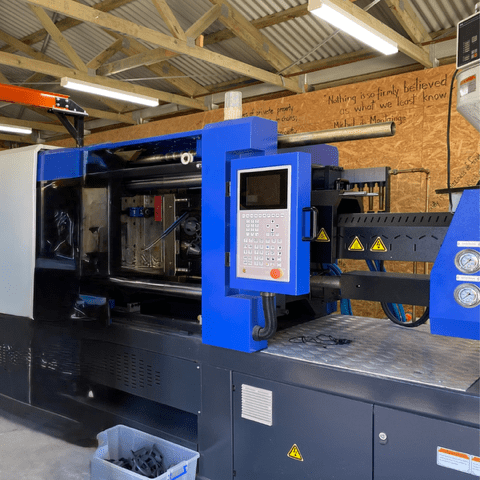

Injection Moulding

We have in house injection moulding capability to bring your product to life.

Contact Us

Tours and Education Programs

We believe through education, demonstration and support we can dispel some of the myths around recycling in Australia.

Contact Us

Supplier of Recycled Resin

We see plastic waste as a high end resource.We can supply an all Australian made recycled plastic with provenance.

Contact Us

Corporate Circularity Projects

We help Brands, Manufacturers & Recyclers turn their waste plastic into high-end next generation products.

Product Design

We are always happy to work with you to explore potential new products! We can help with product designs.

Injection Moulding

We have in house injection moulding capability to bring your product to life.

Contact Us

Tours and Education Programs

We believe through education, demonstration and support we can dispel some of the myths around recycling in Australia.

Contact Us

Plastic Recycling

The plastic recycling technology and machines have been developed by Dave Hakkens with his open source Precious Plastics project. Dave is from the Netherlands and is an inspiration to tens of thousands (and growing) people who are being converted from people concerned about plastic pollution to people recycling plastic themselves. The Precious Plastics project has its own community and devotees and our workshop is just another cog in this international movement.

Get involved in your own community:

The workshop can recycle the 7 types of thermoplastics that are currently in the marketplace. The advantage with the small craft size workshop is that it can take virtually all plastic types and do something with it. The large commercial recyclers tend to only take PET, HDPE and some LDPE as they are easier to process and are commercially viable. This means that the other types of plastics are simply going into landfill. A revolution of these smaller local recycling plants will not only fill this gap but also accelerate the tipping point when plastic becomes a valuable resource worth recycling from an economic as well as environmental perspective.

Types Of Plastics